Wipers

We get a lot of questions about wiring windshield wipers and washer pumps with our Infinitybox system. There can be a lot of complexity with windshield wiper kits because of the functions that need to be managed. There are multiple speeds, which are usually different windings on the wiper motor. There can be intermittent features, which can be controlled by a separate module or by electronics in the switch. There is the park function that is usually controlled mechanically by a cam inside the wiper motor. To compound the complexity, different OEMs managed wipers differently. To make wiring your windshield wipers as easy as possible, we encourage you to think of the switch, the motor and the washer pump as a single system. You are going to power this single system from your Infinitybox system and let the switch manage the windshield wiper functions.

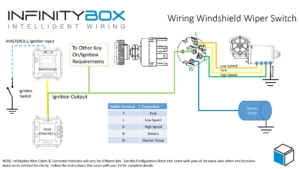

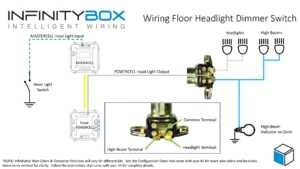

Almost all aftermarket wiper systems work the same way. They include a wiper motor with two separate windings for low and high-speed. The motor also includes a wire that manages the park position of the wipers. These systems may include a washer pump that needs 12-volts to spray windshield solvent on to the window. Lastly, they include a switch that turns on the different speeds, controls the washer pump and controls the park. In general, all of these wiper systems wire the same way. This post is going to look at a universal wiper system. Please read the instructions that came with your kit and contact us if yours looks different. This diagram shows a universal wiring schematic for a windshield wiper kit.

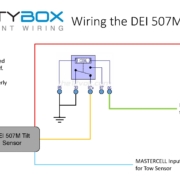

Picture of a wiring diagram showing how to wire a windshield wiper switch to the Infinitybox system.

As we mentioned above, you need to think of this kit as a full system. You are going to power it and let it control itself.

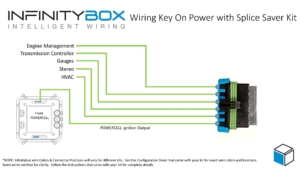

Your wiper switch is designed to take in power from the battery and route that to the different terminals on the wiper motor and the washer pump. To start, there should be a terminal on the switch that connects to ignition or key-on power. In most cases, it is identified with a “B” for battery. You are going to connect this “B” terminal to your POWERCELL ignition output. In most kits, this is the light-green wire on your front POWERCELL but check your specific configuration sheet. You are going to tap into your ignition output to get this power for the wiper switch. You can simply splice into the ignition output wire or you can use our Splice Saver to create an ignition buss bar. Check out this picture to see how you would use the Splice Saver to get your ignition power for your wiper switch.

By using the ignition output on your POWERCELL, your wiper switch will have power when you key is in the ON position. You wipers will not work when the ignition is off. You can also use one of the OPEN outputs in your kit to create an accessory buss bar that would be separate from your ignition output. Click on this link for more details on creating a separate accessory buss.

Once you have the power wired to your wiper switch, follow their instructions for making the connections from the switch to the wiper motor and the washer pump. There are usually connections for the low-speed and high speed windings plus the washer pump. When you turn the switch to the low-speed position, the switch takes ignition power and directs that to the low-speed windings on the motor. It does the same for the high-speed. When you push in on the switch, it sends ignition power to the washer pump.

When you turn the switch off, it puts ignition power on the park wire that goes to the motor. The wiper motor has a cam inside its mechanism that routes power to the low-speed windings until the wipers return to the park position. When they get home, the cam in the mechanism opens a switch that stops the motion of the wipers.

You can download a PDF version of the wiper switch wiring diagram by clicking this link.

Give our team a call at (847) 232-1991 if you have any questions about powering your windshield wipers with our Infinitybox system. You can also contact our team directly by clicking this link.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.